CAM Driven Secondary Operation Machine

CAM Driven Secondary Operation Machine

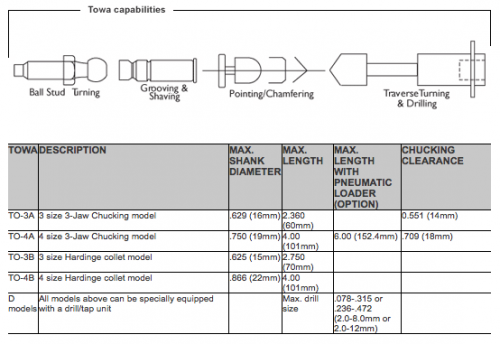

Towa Secondary Operation Machines offer durability combined with hi-speed precision performance

Towa utilizes two tool slides; one tool slide is located in the front and one tool slide is located in the rear. This allows the operator to make more than one processing of the part in one pass.

This design provides flexibility and versatility and eliminates the need for running the parts through twice or moving to another machine. Each tool head or holder can mount two cutting tools. In addition, our front tool slide has the ability for traverse cutting movement.

Towa's system of speed controlled spindle and cam shaft allows the operator to achieve greater control over the range of RPMs of the main spindle and also the pieces per minute production rates.

Models types include: Collect type for gripping the shaft of fasteners and for machining the head; and the 3 jaw type for gripping over the head for machining the shaft of a fastener. Drilling units and drilling/tapping units are optional accessories on both type machines. Dedicated drilling and tapping machines are available upon special request.

Towa machines are mainly used in the fastener industry. It is easily accepted into most plants because it is more mechanical that computer controlled.