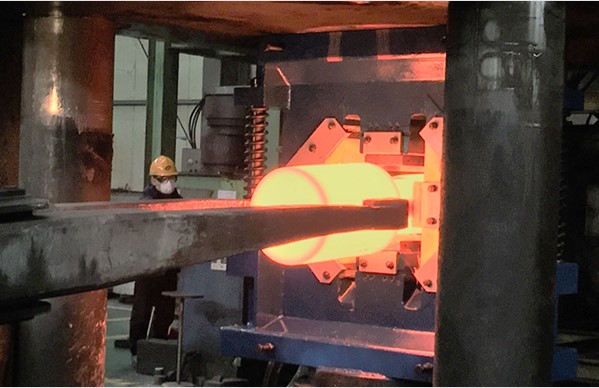

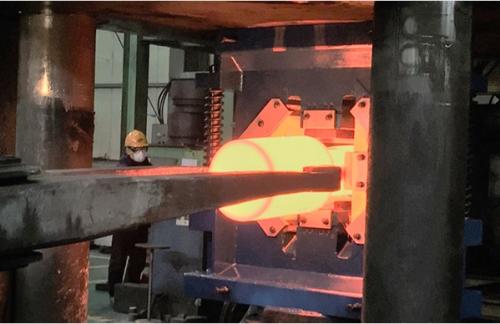

Radial Forging Device

Radial Forging Device

Four-die forging devices are designed to forge material on hydraulic forging press from four sides simultaneously.Four-die forging device is a unique forging tool which combines advantages both of radial forging method implemented on radial forging machine and conventional forging method using with two dies implemented on forging presses.

Four-die forging device is intented to be installed and fixed on the table of hydraulic forging presses with capacities from 2 to 150 MN just in place of conventional dies. It is designed to forge a workpiece with four dies simultaneously so that it generates supplementary shear strains of the material.

Benefits of the four-die forging device :

■ 1.5 ~ 3 times higher output as compared to conventional two-die forging method commonly imployed on presses.

■ 8 ~ 15 percent increased good metal yield.

■ 2 ~ 2.5 times reduced dimensional tolerances of the forged products and 1.5 times reduced allowances for finish surface machining which means 40~50kg of metal saved per 1 ton of forged parts.

■ 30 ~ 40 percent reduced energy consumpion at drawing operation.

■ 25 ~ 30 percent reduced gas consumpition for metal heating due to elimination of reheating requirements.

■ A better isotropy and improved physical/mechanical properties of forged metal.

■ A wide range of steel grade which can be forged in the device and a wider range of finish product shape.