Hot & Warm Forging Press

Hot & Warm Forging Press

High-Rigidity and High-Precision Structure

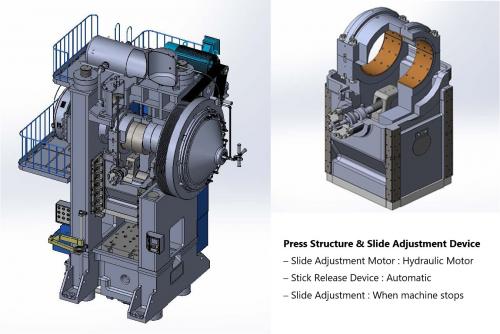

■ Designed for efficiency, the main components comprise upper and lower frame of cast steel (for presses exceeding 2000ton) and an upright of welded steel plate (cast steel in some models), These frames are securely fastened together with four(4) tie-rods, providing an robust frame structure. This approach minimizes thickness variation in forged products and maintains a high level of accuracy. Wide Range of Allowable Eccentric Loads

■ The double con-rod accommodates a wide range of allowable eccentric loads. Moreover, the rigid box-type slide travels in an eight-sided guide that provides the forging rigidity and gib accuracy to withstand inclination. Easily Manipulated Slide-Adjusting Device

■ The die-height adjusting device is mounted in the slide, eliminating problems such as entry of scale and die lubricant. The optional automatic die-height adjustment provides for rapid adjustment during high-speed transfer by combining a hydraulic cylinder and eccentric wrist pin.Revolutionary Stick Release Device

■ This device provides for easy stick releaseEasy Maintenance

■ The oil lubrication ensures that major mechanical components remain clean. Used lubricant is stored in reserve and can be reused after cleaning. (An optional oil circulating system is available). The surface of slide guide is made of hard plate for consistent, long-term accuracy. The brake incorporates block-type friction materials that are simple to use and offer a long service lineEco-Friendly, Energy-Saving Design

■ The main motor can be equipped with an optional vector inverter. The servo and inverter provide optimum control of the drive mechanism.