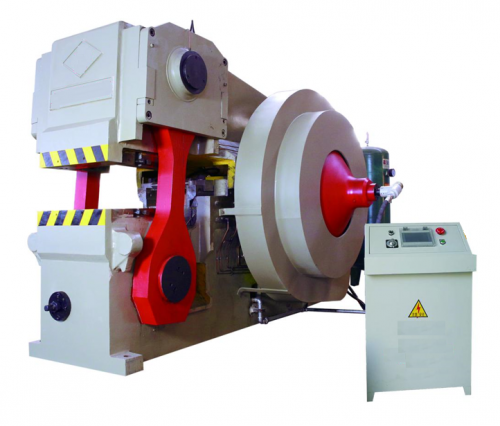

Horizontal Hot Forging Machine

Horizontal Hot Forging Machine

It has wide application range, and is an ideal model of forging extended special-shaped workpiece.Multi-station forming and high degree of automation adoption

■ The machine has multi-station forming, and also can implement full-automatic forging process according to user requirements, which cannot be substituted by other equipment.

High-Rigidity and High-Precision Structure

■ The body structure of the machine is divided into two kinds, including steel plate welding body and integral steel casting body. Through tempering process, the machine has good rigidity, no deformation, adopts the lever principle, has free transmission, low noise, high precision, convenient operation, etc. The equipment adopts the control system with PLC as the core, has the advantages of load-deflection resistance, suitable for multi-cavity forging, fast mechanical pressing speed, reducing the contact time of forgings and dies, thus improving the working efficiency and prolonging the service life of dies.

Wide range of application

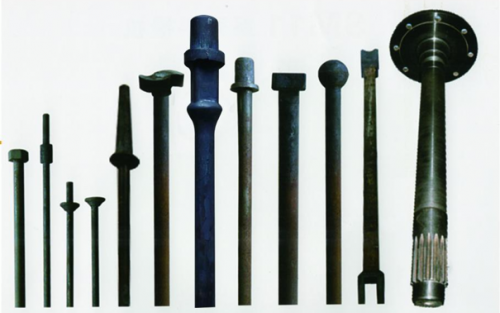

■ The equipment can produce various special-shaped forgings, such as high-speed railway fittings, tubing end reaming holes, sucker rods, socket wrenches, automotive half-axles, valve rods, diamond drill pipes, camshafts, square workpieces, extension bolts, etc.

Overload protection and Energy saving

■ The equipment adopts the insert type dry clutch, safe double valve and electric-controlled automatic lubrication system, the clamping mechanism is equipped with an overload protection device, so as to prevent overload damage in the clamping process, and the humanized equipment can save both time and labor.