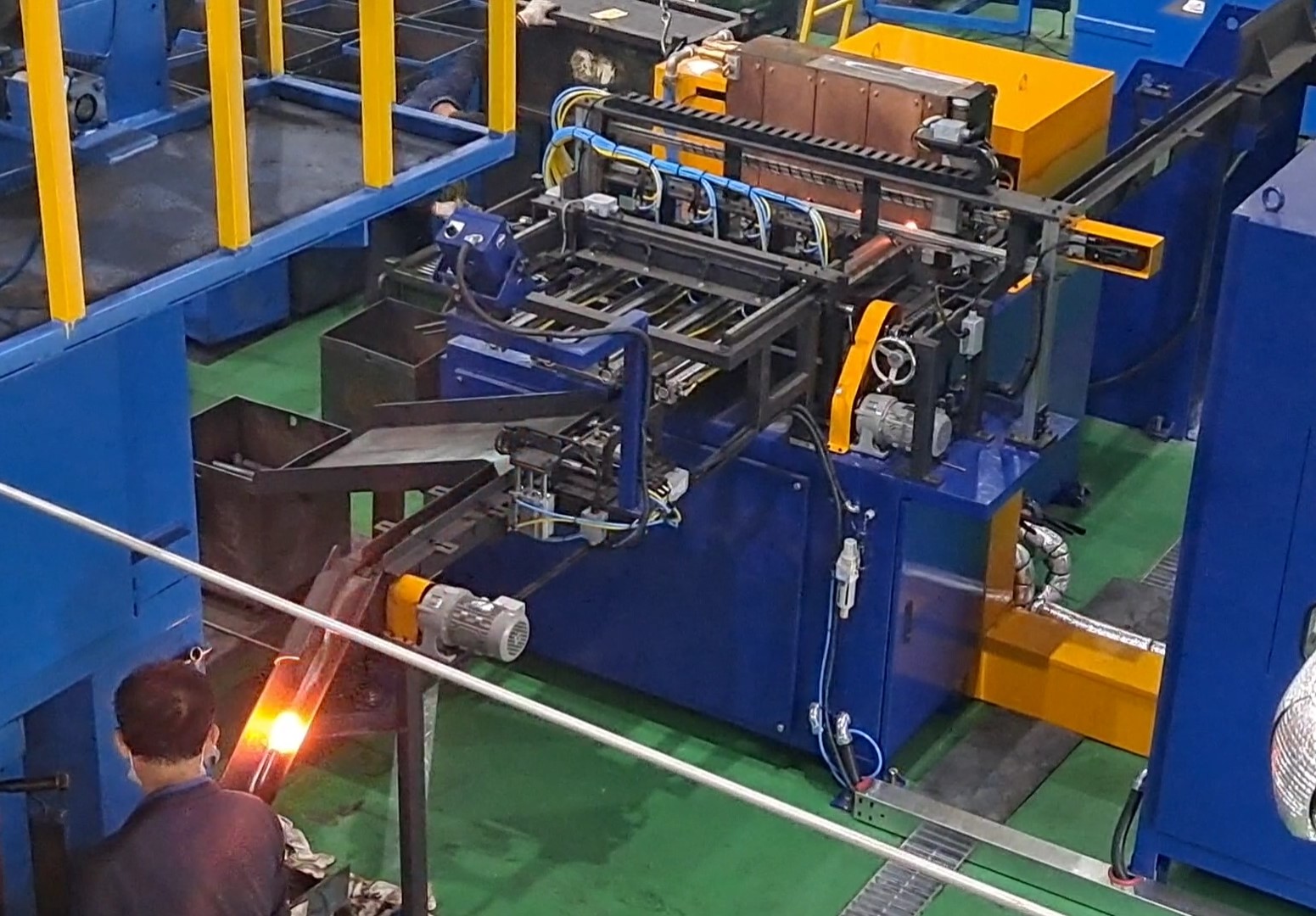

Fully Automatic Bar End Induction Heater

Fully Automatic Bar End Induction Heater

Configuration with bar feeding device, 2 to 5 stages induciton heater and output conveyor■ Bar (material) feeding device with tilting box tipper which can take 300 ~ 500Kgs capacity at once.

■ Bars will be fed into 2 to 5 stages of heating coils by transfer fingers and pusher.

■ Heating lengh can be adjustd by easy setting.

■ Heated bars will be ejected and fed to output conveyor one by one.

■ 4 seconds cycle time is possible, which can heatup and supply 15 pcs per minute.

■ Unmanned operation is possible.

■ Approx. 40% of electricity consumption will be reducded thanks to advanced coil design and heating system technologies with simulation program.

■ Perfect combination with upsetter and hot forging press for yoke parts, shaft parts and hot forging bolt production.